Our Workshops:

Where it All Happens.

Our Henderson workshops are the heart of our operations. The sprawling 12,000m² facility houses 35 high-end machines and 90+ staff, enabling us to deliver unparalleled quality and efficiency across the full scope of engineering, metalwork and fabrication.

State-of-the-Art Machinery.

We’ve equipped our workshop with high-end machinery capable of handling intricate components through to large-scale projects. Our line-up has expanded significantly in recent years, with over $5m invested in new equipment and technology.

- Okuma VTM 200YB

- Okuma GENOS L3000-e: Versatile and reliable for a variety of turning operations.

- Okuma GENOS M560-V-e: Efficient milling with high precision.

- Okuma LB4000EX: Advanced turning capabilities for complex projects.

- Okuma MULTUS B300-W: Multi-functional for both turning and milling.

- Okuma ACE CENTER MB66VB: High-speed, precise machining.

- Okuma CROWN 762S BB: Reliable performance for a variety of cutting tasks.

- Kuraki KBT 13EA: Robust and versatile for heavy-duty machining.

- Mecof CS

- Sanco – CNC Horizontal Boring & Milling Machine

- Kinetic K5000 – Plasma Plate cutting system: Fast and accurate

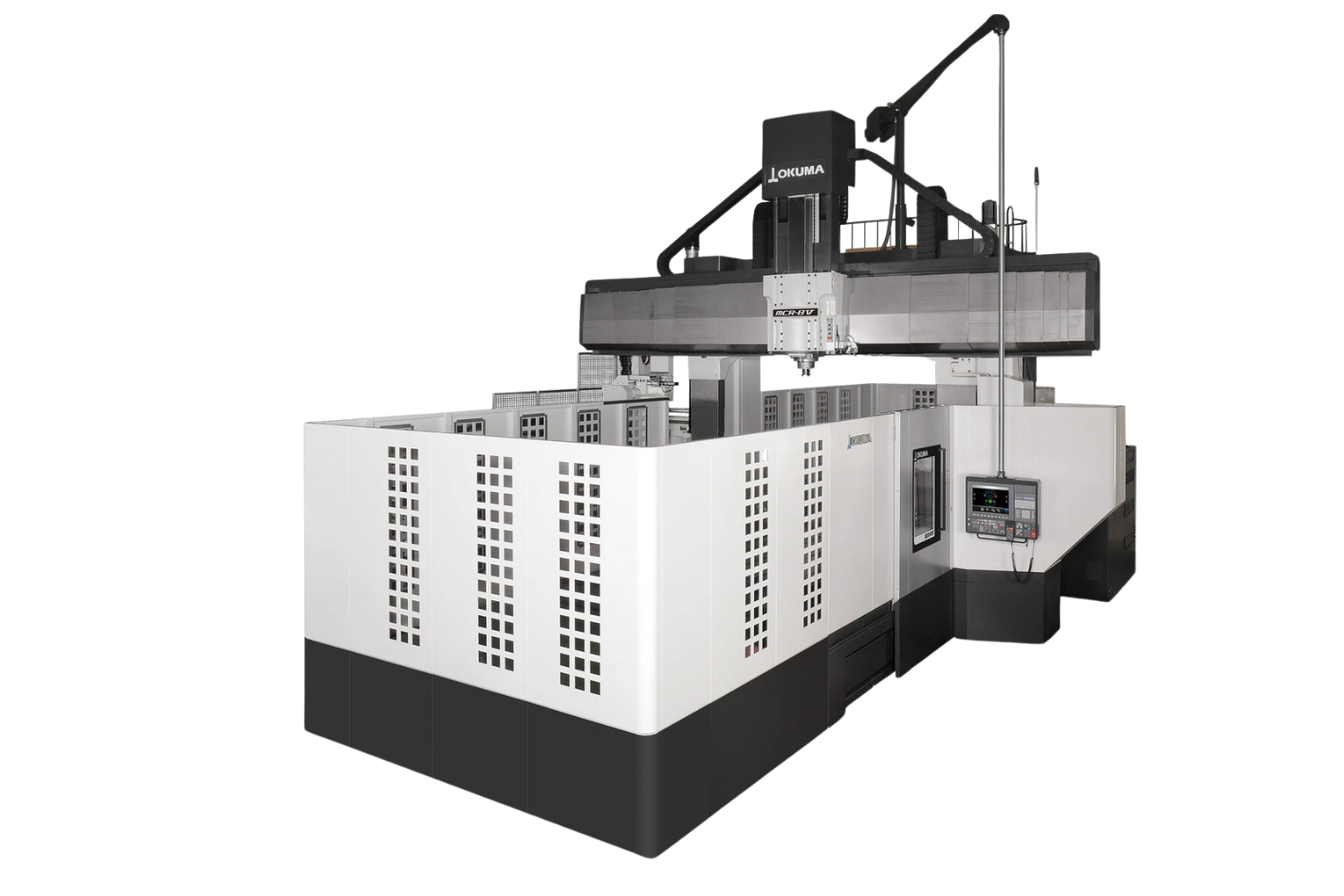

New in 2024: Okuma Double Column

To meet increasing demand from our clients in Mining, Oil & Gas and Transportation, we’ve commissioned one of the largest machining centres in Western Australia.

Advanced Technology.

As well as growing our processing capabilities, we’re also investing in technological innovations.

- CAD/CAM software for efficient design and manufacturing

- CFD/3D analysis software for in-depth project evaluation

- Enterprise Resource Planning (ERP) for streamlined project management

- Nesting software for optimised CNC cutting

Investing in technology drives innovation and process improvements, allowing us to exceed your expectations.

Processes that Ensure Quality.

Our commitment to quality is woven into the fabric of our workshop. Our integrated Business Management System combines the principles of ISO 9001 (quality), ISO 14001 (sustainability), ISO 45001 (safety) and AS/NZS 4801 (OHS) into our daily operations. Every project also undergoes 10 inspections on average before being signed off.

This ensures every project adheres to the highest standards of quality, environmental responsibility and safety.

The Team Behind the Excellence.

High-end machinery is great. Technology is useful. But it’s our exceptional team that truly sets Kerr Engineering apart. They are the engine of our innovation and the reason we’re able to deliver outstanding results every time.

- 90+ people and growing

- 12 mechanical and engineering disciplines

- 4 unique accreditations

- Fully integrated teams for seamless project management

Our Commitment to Continuous Improvement.

A relentless pursuit of efficiency ensures we remain at the forefront of innovation in engineering. Continuous improvement has been embedded in our culture for over 50 years. We continually challenge ourselves to do better across our operations, including safety, decision-making, process flows, project management and client service.

$5,000,000

invested since 2020

99%

50+

Your Full-Scope Engineering Partner.

Our Henderson HQ is a busy place. All our work happens in-house, allowing us to manage your project more efficiently and monitor quality at every stage. As a full-service engineering partner, we’re equipped to support with:

- Design and engineering

- Fabrication and welding

- Machining

- CNC cutting

- Bending and rolling

- Abrasive blast and paint

Discover the Kerr Engineering difference – where precision, innovation, and quality create exceptional results.

Contact us.

To learn more about how the team at Kerr Engineering can help you, get in contact.